Slurry technology | Top technology for all needs

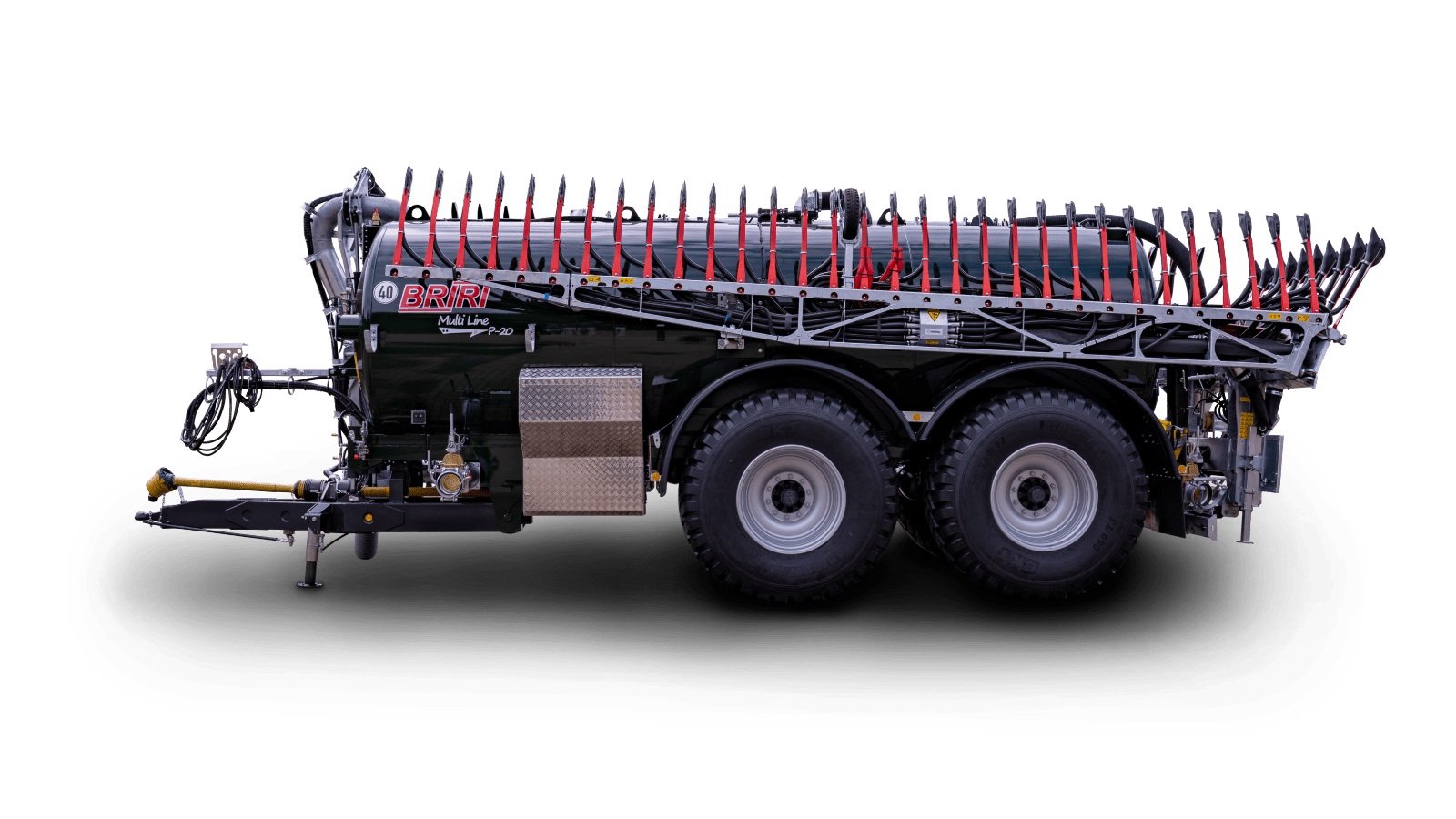

BRIRI has established itself in slurry technology. Our company has represented perfectly high-quality products in slurry spreading for more than half a century. Ongoing development with an innovative view to the future enables us to constantly expand our product range and develop vehicles with cutting-edge technology for slurry spreading. Small, medium-sized, and large operations, contractors, and machinery cooperatives alike will find what they are looking for at BRIRI! See for yourself!

Basic Line

Manure spreader | Efficient solid-manure spreading

BRIRI manure spreaders are an efficient and powerful solution if you want to spread your fertiliser as solid manure rather than as slurry. Robust, high-quality frame constructions and stable axles in combination with superior spreader units turn these spreaders into unique all-rounders in the field. BRIRI offers some innovative vehicles with unique spreading quality and maximum precision: the Manure Instructor (previously E-series), the Manure Director, and the UTS series.

Manure Instructor

Manure Director

UTS

Manure Professor

Transport technology

Silo-Trans

Road Master