Control technology / precision farming

Tractor control units

All functions are controlled via the tractor’s control units as a basis for operating versatility. The scraper floor feed can be adjusted proportionally via a potentiometer in the cab even in the unit’s basic version.

All functions are controlled via the tractor’s control units as a basis for operating versatility. The scraper floor feed can be adjusted proportionally via a potentiometer in the cab even in the unit’s basic version.

Control panel

The next level will supply oil via the tractor’s LS connections. All switching functions are available on a central control panel. An indicator light for the tailgate position is integrated in the control box in addition to the infinitely variable feed regulation.

The next level will supply oil via the tractor’s LS connections. All switching functions are available on a central control panel. An indicator light for the tailgate position is integrated in the control box in addition to the infinitely variable feed regulation.

ISOBUS

The spreader is equipped with an ISOBUS control unit in the highest category. Oil is also supplied via the tractor’s LS connections. This operating concept opens up a wide range of options. It permits convenient control of all functions via the tractor’s integrated terminal (provided that an ISOBUS-capable operator terminal is available) or via an external ISOBUS-capable terminal. BRIRI offers 8.4" and 12" terminals for this purpose.

Operation can also be made easier with the help of an AUX-N-capable joystick. Completed work can be recorded and documented via the connection to a task controller. It is then available for further processing.

Precision Farming

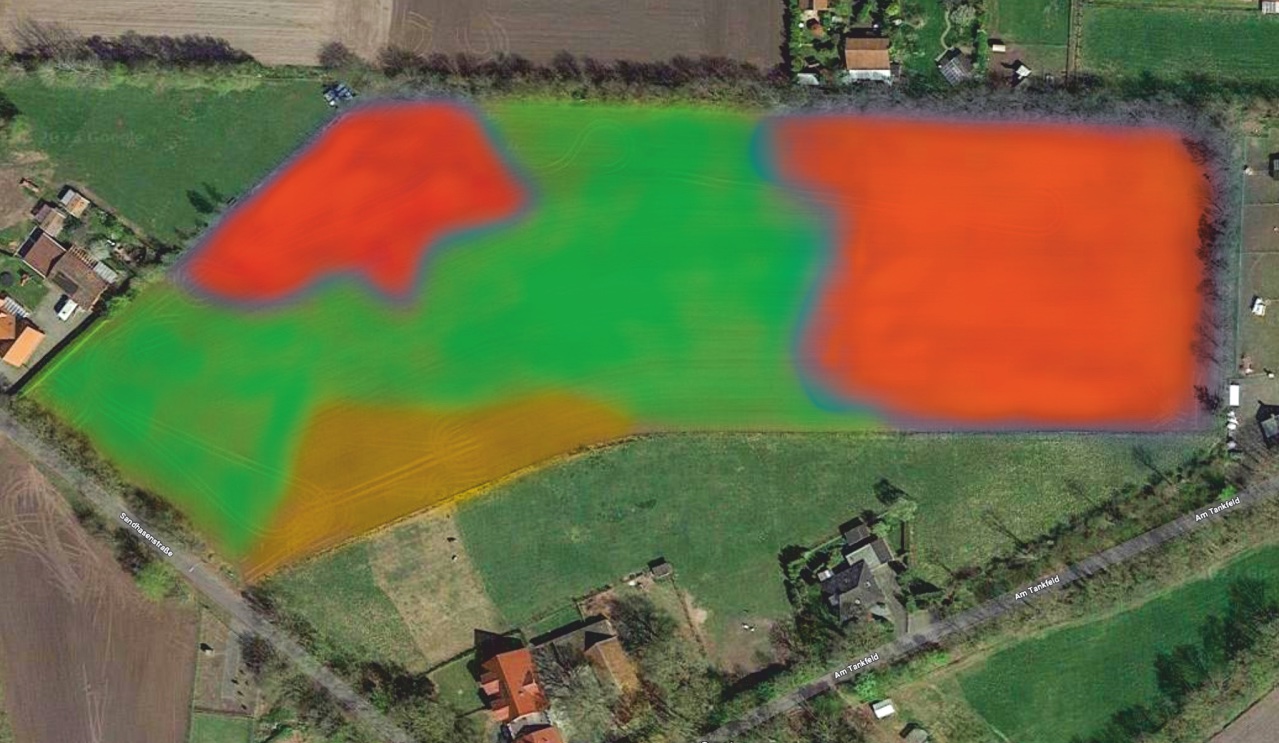

Fertilising specific areas

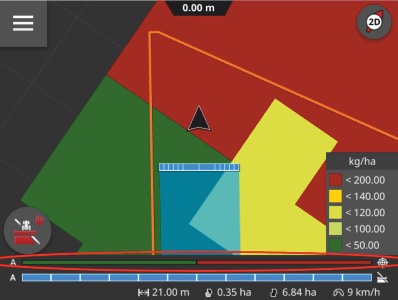

It is possible to implement partial area-specific fertilisation in combination with an ISOBUS control unit and the associated TC-GEO activation system.

Section-specific fertilisation is an important aspect of precision farming. The differences in soil and growth within an area are considered in this fertilisation method. The goal is applying the determined fertiliser in the right place at the right time and in the right quantity.

Application-rate adjustment

The feed speed can be adjusted manually and smoothly from the cab in the lowest configuration level. The next level will control the scraper floor automatically based on volume.

The feed speed can be adjusted manually and smoothly from the cab in the lowest configuration level. The next level will control the scraper floor automatically based on volume.

The full equipment has its application rate adjusted fully automatically based on weight. This requires a weighing device. Dynamic control is possible while spreading or following advance calibration. We recommend the latter for minimum application rates.

The application rate control is available in three expansion stages. In combination with the automatic application-rate regulation via the weight, the ISOBUS control unit can work with application maps and thus also fertilise specific areas only.